DTF(Direct to Film) Manufacturer and Supplier

With more than 10 years of experience

Professional DTF(Direct to Film) Manufacturer

Our Products

Types of DTF Supplies

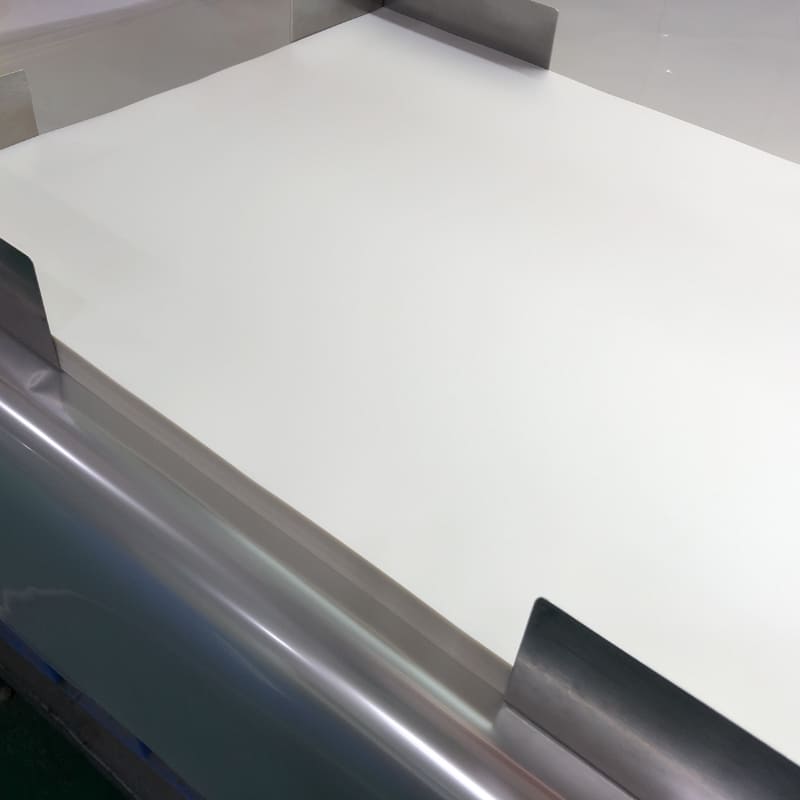

DTF PET Transfer Film Roll

DTF water-based white ink printing film is a new type of digital heat transfer printing film. Our DTF printing films are easy to peel off and have bright colors. Has good ink absorption and breathability. Compared with weak solvent printing, it has better environmental protection.

Advantages of DTF PET Transfer Film Roll:

-

Compatible hot or cold peel off

-

Strong ink absorption

-

No holes, bubbles

-

Easy to peel, easy to shake powder

-

Vivid and colourgul

-

Shelf life 2 years

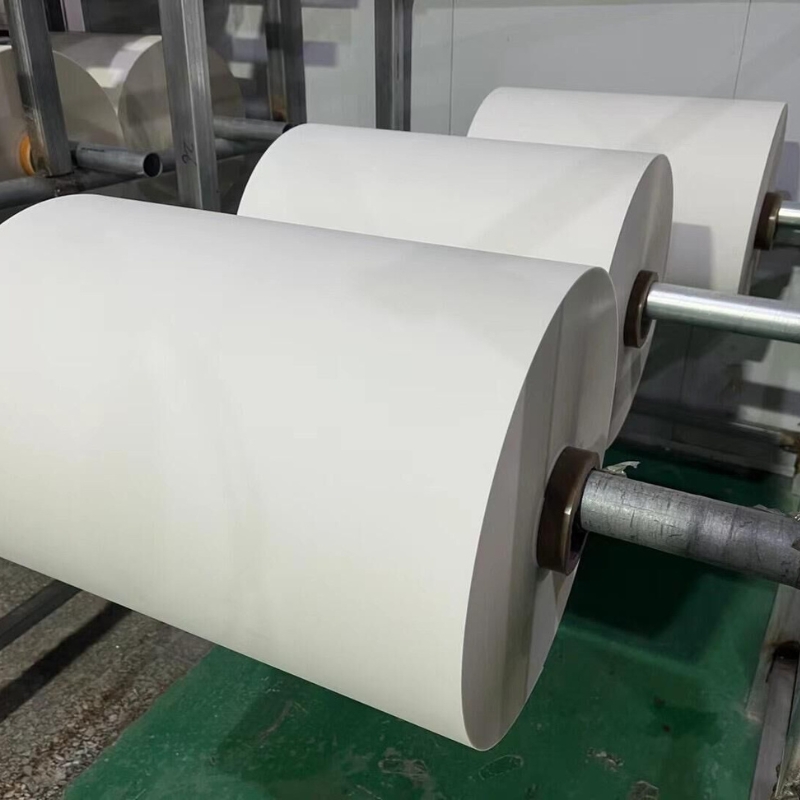

UV DTF Film

Polyester transfer release film is release coated pet film (PET release film) that is coating silicone on pet film which is used as hot peel or cold peel transfer. It can be screen printing, digital printing and litho printed transfer. Compare with the release paper, PET transfer film is stronger, easy to release and high transparency and more smooth surface.

DTF Ink

DTF Printing film ink heat transfer printing film ink is a new type of water-based paint ink, which has good ink stability, good fluency, and reduces the maintenance cost of the bumper. CMYK color ultra-high density, brilliant and saturated color, strong white ink covering power, high whiteness. White color inks have good compatibility and do not penetrate each other.

Advantages of DTF PET Ink:

-

Good fluency

-

High precision

-

Saturated and vivid colors

-

Good color fastness, rubbing resistance, not easy to fade

-

Stretching and not easy to crack

-

Good machine protection

Why Choose Us

Product Effect Display

FAQs

Online

You can text online messages to us, leaving your name and contact information. Our service team will reply to you in short time for further negotiation.

Phone

Call us and our customer service representatives are ready to help you and answer any questions. For quicker processing, have the item number of the product you wish to purchase ready when you call.

Send your inquiry detail or purchase order by mail info@heattransferfilms.com.

All products are made with first-class raw material, our all production lines are automatic and free of dust level.

Before production, our quality team will check our raw material carefully, guarantee no any issue then go on the production, after that we will recheck the finished products.

Before shipment, our quality test team checks every piece of our goods again, 3 times checking to guarantee our all shipment goods are high quality and standard.

Before you send the order, we will arrange the sample for your test, we promise all order's quality are kept the same as the sample quality which is confirmed by our customers.

As normally, we ship the goods by sea or by air depending on the good's weight, quantity and customer request.

The degree of export packing required moisture protection, fixed stronger no damage. So we used the first-grade pp film inside packing, then pack in 5mm thick cardboard. At last put on non-fumigation pallets.

Secondly, our all warehouse person is full experienced in export goods packing, they will save the package volume by different specification mixed packing to save your freight cost.

24/7 online customer support. After-sales service stays in touch with the customers even after the deal. Whether the customer is happy with the products or not? By each other good communication, our customers will believe in our brand. We take it as an important part of our company culture.

Create a section in the website where the customers can feedback anytime. Our customer service team should take prompt action on the customer's queries. The problems must be resolved immediately.

We agree to replace the products if found faulty also offer variable warranty policies to customers.

Production Capacity and Inventory

QianTai is a professional manufacturer of PET Transfer Release Film and transfer media in China with a history of more than 10 years. QianTai has a complete set of production equipment and pollution treatment equipment, with strong production capacity and ability to digest orders. And to ensure green production, raw materials are non-toxic and harmless, the production process is environmentally friendly, and help circular economy. And we have a certain stock of inventory, which can meet the urgent needs of customers in a timely manner.

Quality Inspection

-

Responsible for the operation of the quality management system to ensure the high quality of products.

-

Designate inspection standards, clarify inspection methods, inspection procedures and non-performing matters.

-

Responsible for the collection, summary and analysis of customer satisfaction information, and take measures to improve and perfect the quality work.

-

Ensure product quality can meet customer requirements.

DTF (Direct to Transfer Film) is a revolutionary printing technology that uses a DTF printer, DTF ink, DTF powder, and a heat press. This method is more time and cost-efficient compared to DTG, laser toner, or screen printing technologies. DTF transfer films, available in matte or glossy finishes, can be peeled at different temperatures (cold, warm, or hot) according to user preference and come in thicknesses primarily of 75micron or 100micron. Sizes vary as customers request, either in sheets or rolls.

These films exhibit excellent dimensional stability during heat processing. As leading DTF PET transfer film manufacturers in China, our unique formula is crucial to the high-quality performance of our films before market release.

What is DTF in Printing?

DTF printing is an innovative garment decorating process that serves as an alternative to DTG. This method involves printing with water-based ink onto DTF transfer films, followed by drying in a heating tunnel, applying DTF powder to the back, and then heat curing. A significant advantage is the elimination of the pre-treatment stage. Images are transferred onto garments within 10 to 15 seconds of heat pressing. DTF is versatile, accommodating a wide range of fabrics including cotton, polyester blends, rayon, nylon, silk, leather, and more.

This low-cost investment is ideal for small batch production and stands as a significant enhancement in the printing industry, complementing screen printing, white toner printing, and DTG. Our DTF films are designed for use with various printers, including desktop and large format models.

The high-quality DTF ink and powder we use ensure a soft hand feel, excellent color fastness, and resistance to washing, making it ideal for sportswear, jerseys, and work clothes.

Essential Elements for Effective DTF Printing

- Invest in high-quality DTF equipment, including printers and heat presses, to achieve the best results.

- Use superior DTF ink to avoid clogging print heads, ensuring high color density and saturation for durable prints.

- Select high-grade DTF transfer films that are specifically processed to withstand high temperatures and pressures, compatible with all printer types.

- Choose quality adhesive powders that enhance the image's adhesion to fabrics, proven through extensive wash tests and ensuring a soft touch without any peculiar smell.

DTF Direct to Film Printing Process

- Preheat the garment to remove moisture (Temperature: 325 F, Time: 10-15 seconds, Pressure: Medium to heavy).

- After heat pressing, wait for 10 seconds then peel hot.

- Press again for 5-10 seconds without a cover sheet to fully cure the shirt.

- Allow 24 hours before washing or stretching the garment.

For thick or coarse-grained fabrics, or small letter designs, adjust by pressing for an additional 5 to 10 seconds under heavy pressure. If the transfer lifts during peeling, allow it to cool completely before attempting again, or slightly increase the temperature and pressing time for complete curing.

Which is Better: DTF or DTG?

DTF and DTG both offer benefits for digital garment printing but serve different needs. DTF is faster and more versatile across fabric types, ideal for quick turnarounds and extensive fabric ranges. DTG excels in quality and color vibrancy but is slower and suited for smaller orders. The choice depends on the specific project requirements.

Is DTF Better Than Vinyl?

Both DTF and vinyl printing have their merits. DTF provides vibrant color reproduction and a soft fabric feel, perfect for detailed designs on various garments. Vinyl is durable and withstands rough conditions but may not match DTF's color vibrancy or texture. Your choice should be based on the print's intended feel and durability needs.

Choose Professional DTF(Direct to Film) Manufacturers and Suppliers

As the top DTF(Direct to Film) manufacturer in China, our service team has more than ten years of industry experience, they will provide you with a comprehensive PET Heat Transfer Film solution, and work with you between your requirements and costs Find the balance.

Provide pre-sales and after-sales assistance by phone or email, and our service team will provide you with timely support. We will be your reliable long-term partner.

If you have any questions or need customized services, please contact us immediately, we will give the best solution!

Leading DTF(Direct to Film) Manufacturer

Contact us today and let our team of experts guide you in choosing the perfect DTF (Direct to Film) for your specific needs.